How To Install Commercial Tile

How to Lay a Vinyl Tile Floor (VCT flooring)

You can lay a good-looking vinyl tile floor in a weekend.

If you're skilful at measuring and are comfortable using a utility knife, y'all'll have no problem installing a basic vinyl composition tile (VCT) floor.

You lot might also like: TBD

- Time

- Complexity

- Cost

- Multiple Days

- Intermediate

- $101–250

Programme ahead for VCT flooring

What is VCT Tile?

At beginning glance, this floor might not wait similar information technology's made of the aforementioned blazon of vinyl tile that yous may remember from your parents' rec room. Only like bong-bottoms and miniskirts, vinyl tile is back. It'due south inexpensive, nigh indestructible and easier to install than almost other flooring materials. The best function is the space number of designs yous can create once you larn a few special techniques. In this article, we'll become beyond basic flooring laying to prove you how to programme and install a decorative edge and how to insert custom shapes into the floor tile. If you're good at measuring and are comfortable using a utility pocketknife, you'll have no problem installing a bones vinyl composition tile (VCT) flooring. Our design incorporates circles, but cutting and installing the circles isn't for everybody. It requires patience, attention to detail and a stiff, steady paw. Expect to spend about a mean solar day preparing the floor, and then a few more days laying the tile, especially if you're installing a flooring like ours with borders and custom-cut decorative tiles. You can install a simpler floor without a border or custom tile using the techniques nosotros'll show y'all and be done in virtually a day.

Don't settle for what's on the shelf—special-gild the colors y'all want The vinyl composition tile (or VCT flooring) we're using costs about 60¢ to 90¢ per foursquare human foot. The almost common size is 12 in. square and 1/eight in. thick. Although it'due south relatively easy to cut with nothing more than a straightedge and sharp utility knife, nosotros'll exist using a special VCT flooring cutter for speed and precision. You'll find a few basic colors of VCT flooring in stock and tin can special-order others. Unlike other modern flooring fabric, VCT flooring does have to be polished to maintain a shine.

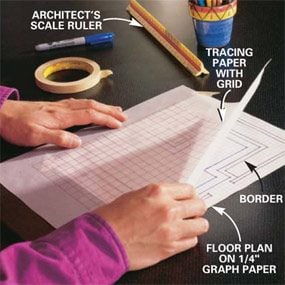

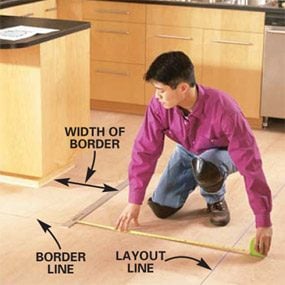

A scale plan makes custom floor design easy Before yous showtime shopping for tile, measure out the room and draw a calibration plan on ane/iv-in. graph newspaper (Photograph 1). Your goal is to make the cut tiles along the border (or wall if yous won't be installing a border) as large every bit possible. If you get stuck with skinny tiles, place them along an inconspicuous wall. When you lot find an organisation you like, transfer the floor plan from the graph paper to a tracing paper grid and make a few photocopies. At present utilize colored pencils to experiment with different color combinations. Later you complete the floor plan, count the number of tiles. Order your tile, calculation xv percent for waste product. You lot'll probably accept to order full cartons (well-nigh 45 sq. ft. per carton) of each color. Wait to wait a week or ii for the tile to get in. In addition to tile, y'all'll need latex agglutinative specifically for VCT flooring; check the characterization to be sure. This calorie-free-colored adhesive spreads easily, has no dangerous solvent fumes and cleans up with water while it's wet. I gallon covers well-nigh 200 sq. ft. and costs $15 to $20.You'll besides demand transition strips at doorways and openings into other rooms and forest base shoe molding to encompass the edge of the tile along walls and cabinets.

Careful floor prep is the key to a smooth floor

Fifty-fifty these 1/eight-in. thick vinyl tiles won't encompass up bumpy floors. Concrete must be structurally audio and dry out with no large cracks or uneven sections. Scrape or chip off bumps and fill low spots with floor-leveling compound. A layer of underlayment (lauan or other special plywood, $12 to $20 per 4 x 8-ft. sheet) should be installed over wood floors to create a smoothen, make clean surface for the tile. Underlayment is available at home centers and lumberyards.

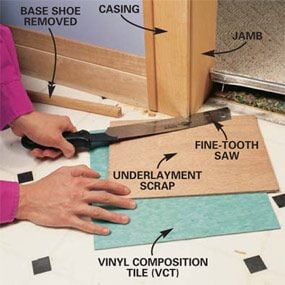

Remove base shoe moldings, door thresholds and metal carpet strips, then undercut the door casings (Photo 2). Let the underlayment to acclimatize to the humidity in your business firm for a day or two. Then cutting information technology and staple it downwardly (Photograph 3). You'll demand nigh sixteen staples per square human foot, and then rent a compressor and a pneumatic stapler that drives narrow crown (ane/4- or iii/16-in.) x7/eight-in. long staples for large floors (Photo 3). Again, a smooth, make clean surface is essential. Level uneven seams in the underlayment by filling the low side with floor filler (available at dwelling centers and flooring retailers).

Caution!

Many old vinyl floors and the adhesive used to install them incorporate asbestos. Because asbestos tin exist hazardous when it's disturbed, it's improve to embrace onetime vinyl floors with a layer of underlayment than to tear them out.

Gluing downwardly the VCT flooring tile

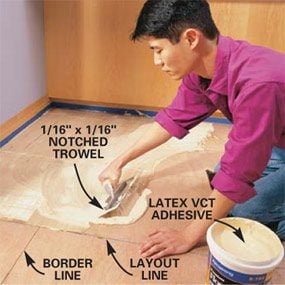

The glue we utilise allows hours of working time With the layout lines marked in pencil, you're set to roll. Sweep the floor carefully; even a tiny chunk of dirt will eventually bear witness through the tile. And so pour a mound of agglutinative on the floor and spread information technology (Photo six), starting at the uttermost corner and working upward to the lines. Keep a wet rag handy for wiping your hands and cleaning up excess mucilage. Dried glue can only be removed with mineral spirits or special adhesive remover.

Once the adhesive dries and turns clear, you'll take at least half-dozen hours to lay tile—plenty of time to finish tiling the first half of your floor, including the cutting.

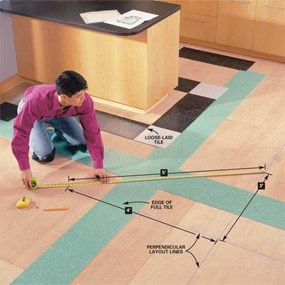

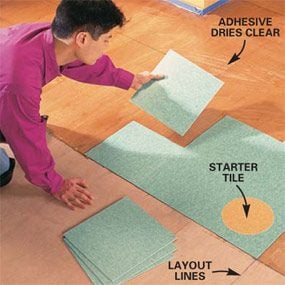

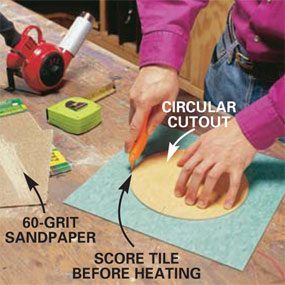

The special VCT flooring cutter simplifies the piecework You lot'll be able to encounter the layout lines through the dried agglutinative. Place tiles carefully, because subsequently they're pressed into the adhesive, they're very difficult to remove or reposition. Using the stair-step technique (Photo vii) will help y'all go on the tile edges precisely aligned and tightly butted together. Refer to your plan for placement of special decorative tiles—in our case, circles. You'll notice a "grain" pattern in the tile. Some installers turn every other tile 90 degrees for a checkerboard effect. We chose to keep the grain running in the same direction. To meet which look you prefer, experiment by loose-laying some tile on a dry floor. Lay all of the full tile. Then measure and cut the partial tiles needed to fill out to the border line. You may have to notch a tile for an inside or outside corner or to cut around a cabinet. Photograph eight shows how. Rent a VCT floor cutter ($13 per day) to ensure precise, clean cuts (Photo 9). If your rental store doesn't take a VCT flooring cutter, you lot can cut tile on a table saw fitted with a sharp carbide finish blade (wear a dust mask, safety spectacles and hearing protection). Another option is to score forth a straightedge with a precipitous utility pocketknife and break the tile along the scored line. Clean upward rough edges with a file or lx-grit sandpaper.

Complete the field tile, then lay the border. Don't worry if the joints betwixt the border tiles don't line upwards with the joints in the field tile. Showtime by laying full tiles at the corners. Then cutting the final tile in each section to fit (Photo x). If by bad luck the last tile is going to be less than 1 in. wide, cut an inch off the previous tile to make the terminal 1 larger. Complete the flooring past filling in the tiles betwixt the blackness border and the wall (Photo 10). Cutting these tiles so the joints marshal with those of the border tile. You'll end up with a squeamish-looking square tile at within corners, but yous might accept to notch a tile to become effectually an exterior corner.

CAUTION!

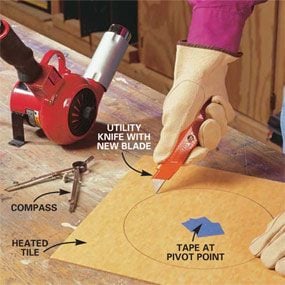

Keep your hand and fingers out of the path of the utility knife, and wear heavy leather gloves for protection.

Create your own custom tiles

Photos 12 – 14 show how to create custom tiles. But don't expect perfect results without a fiddling practice. You don't have to make circles. Apply the same procedure to brand any shape you can imagine.

Purchase special accessories to simplify transitions

There are many ways to make transitions to other types of floor. But the best way is to apply special reducers designed for each situation. Photograph 11 shows a professional person method for finishing a raw carpeting edge. Ask your floor retailer to recommend transition pieces for your flooring.

Routine cleaning and care will aid your floor last decades

Clean excess mucilage from the face of tiles with a damp rag or mineral spirits. So rent a 100-lb. floor roller ($thirteen a day) and roll the flooring to ensure a tight bond between the tile and agglutinative. Reinstall your old base of operations shoe moldings or cut and install new ones.

Allow four or five days for the adhesive to fully cure earlier washing and sealing the floor. To fix it for sealing, sweep the floor and clean it with a mild neutral detergent like Armstrong S-485 Floor Cleaner. Use a non-abrasive scrub pad to remove stubborn marks. Allow the flooring to dry before applying several coats of high-quality acrylic floor polish or sealer.

Required Tools for this Project

Have the necessary tools for this DIY project lined upwardly earlier you start—yous'll relieve time and frustration.

Heat gun, VCT flooring cutter (rent for $13 a twenty-four hours), compressor and narrow crown pneumatic stapler, 100-lb. flooring roller (rent for $13 a twenty-four hour period), Fine-tooth saw

Required Materials for this Projection

Avoid concluding-minute shopping trips by having all your materials ready ahead of time. Hither'due south a listing.

Source: https://www.familyhandyman.com/project/how-to-lay-a-vinyl-tile-floor/

Posted by: mathersvengland.blogspot.com

0 Response to "How To Install Commercial Tile"

Post a Comment